A hydro dam excitation system uses high volumes of water flow with a vertical drop to create enough force to turn hydro turbine generators. These hydro generators then convert the mechanical energy from the turbine into electrical energy using an excitation system (commonly used for hydro generators because of its superior response and sustained fault support capabilities). Hydropower supplies around a fifth of the World's electricity requirements and is now the largest source of renewable energy in Mexico.

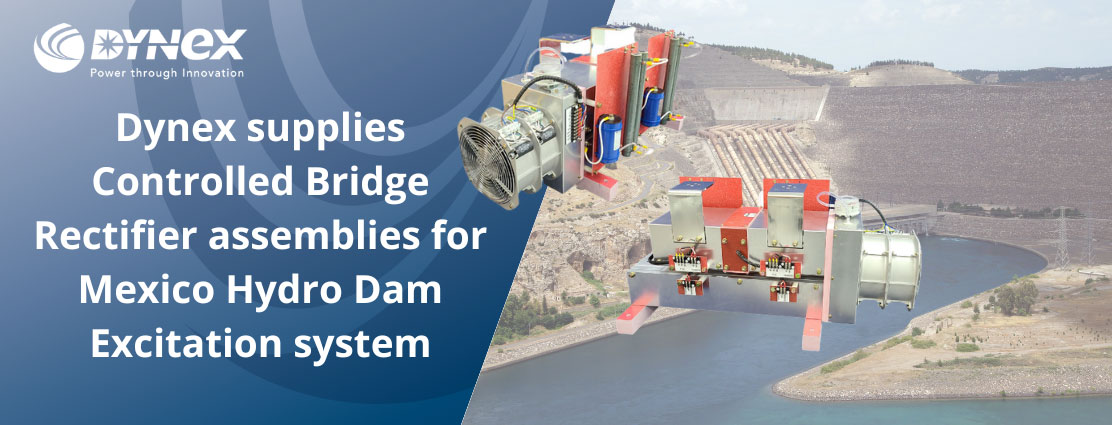

Dynex are proud to have won the contract to supply AP1 Controlled Bridge Rectifier assemblies for one of the hydro dam excitation projects in Mexico.

The Dynex standard power assemblies range of controlled bridge rectifiers consists of proven high reliability Heatsink Assemblies for a challenging range of power generation and renewable energy applications. The DSS600AP1-B6C-2500, DSS700AP1-B6C-2100, DSS900AP1-B6C-2200, DSS1300AP1-B6C-1700 and DSS1400AP1-B6C-1000, are all controlled bridge rectifiers spread across 3 individual phase arm assemblies. Each assembly includes a specific voltage low-switching-loss thyristor.

The forced air-cooled design has been optimised for high reliability operation for deployment in applications that require continuous operation and long lifetime. The Thyristor characteristics have been tailored specifically to lower the overall losses of the assembly to improve reliability as well as increase efficiency. The design can be altered to suit specific application requirements.

Features of the API controlled bridge rectifier assemblies

- High Reliability Proven Design

- Low switching loss Thyristor

- Forced Air Cooling

- Option for back-up for primary fan

- RC Snubber

- Pressure Switch

- IR Temperature Sensor (Optional)

- DC Fuse (Optional)

- Gate Drive (Optional)

- Designed for ease of maintenance

Dynex engineers are engaged in providing tailored power assemblies for hydro dam excitation, power factor correction and rail traction. Dynex are also part of several hydrogen production projects powered from grid distribution.

For more information, contact us to arrange a meeting with our team at powersolutions@dynexsemi.com