Dynex Semiconductor offers a wide IGBT product portfolio which serves critical applications, including automotive, renewable energy, industrial, and rail systems. For renewable energy and industrial systems, Dynex supplies both discrete and power modules at various voltage levels i.e., 1.2kV, 1.7kV, 2.3kV, with various circuit configurations from single-switch to power integrated modules (PIM). These products provide compact solutions that facilitate the design of power converters with small footprints for PV, battery storage, and wind turbine systems, as well as industrial motor drives, ranging from a few kW to several MW. Dynex’s IGBT portfolio for rail applications, spanning 1.7kV to 6.5kV IGBTs, supports main traction and auxiliary converter for metros, locomotives, and high-speed trains of which supply voltages are from 750V to 3kV, ensuring reliability and long lifetime under harsh operating conditions. In addition, special emphasis is given on delivering unrivalled reliability and performance for automotive powertrain applications up to 800V, where Dynex’s 750V and 1.2kV IGBTs ensure exceptional power and thermal cycling capabilities, making these modules ideal for traction inverters, onboard chargers, and DC–DC converters in electric and hybrid vehicles.

Rail solutions: British-engineered reliability and efficiency

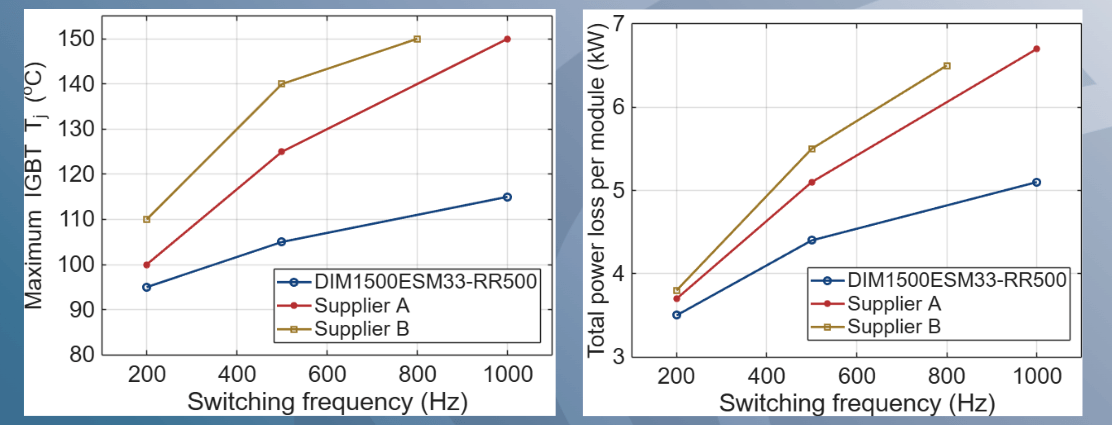

Dynex’s rail solutions embody the hallmarks of British-engineered reliability, delivering exceptional robustness with proven short-circuit withstand capability, and extended lifetime in demanding environments, ensuring that rail operators benefit from reliable, energy-efficient power converters that support safe, cost-effective, and low-maintenance rail traction systems. Rigorous simulations and testing validate the ability of Dynex IGBT modules to maintain high conversion efficiency. Fig.1 shows the simulation results considering a 2.1MW traction inverter for rail application, where the Dynex 3.3kV/1500A module is compared with two equivalent modules from other suppliers. It is evident that the Dynex module can provide significant benefits in terms of efficiency gains due to the reduced total power losses compared to the modules of other suppliers. Moreover, our product achieves lower maximum operating temperature over the entire switching frequency range, ensuring reliable operation and long lifetime.

From planar to advanced trench architectures

Dynex has transitioned from 4th generation planar IGBT technology to advanced 5th generation trench-gate architecture for 3300V and above IGBT products, yielding significant performance gains, since trench chips have increased current density and lower on-state collector–emitter voltage (Vce), resulting in significantly improved power density and performance.

For the most demanding automotive and renewable energy applications, Dynex deploys the latest super-fine trench-gate chips, rated for continuous operation up to 175°C, ensuring maximum efficiency and reliability under extreme thermal stress conditions. Building on these, Dynex is also releasing the reverse-conducting IGBT chip, aiming to further improving electrical and thermal performance by integrating the diode functionality directly into the IGBT structure.

Environmental leadership and sustainability initiatives

Dynex demonstrates comprehensive commitment to environmental stewardship through both product design and manufacturing practices. All UK manufactured semiconductor products are lead-free (Pb-free), eliminating toxic materials and complying with relevant standards, while still maintaining performance and reliability. Moreover, our ISO 14001 and ISO 50001 certifications underpin the environmental management standards and ethos employed at Dynex; this is highlighted by a major expansion of rooftop photovoltaics—from 200kW in 2021 to 428kW in 2023, with over 1,300 panels installed—alongside many energy saving initiatives including LED lighting upgrades, an integrated boiler-and-CHP heating system, and replacement of inefficient transformers and chillers.

For more information about our IGBT solutions or to speak to our technical team to find the right IGBT module for your project, Contact Us.